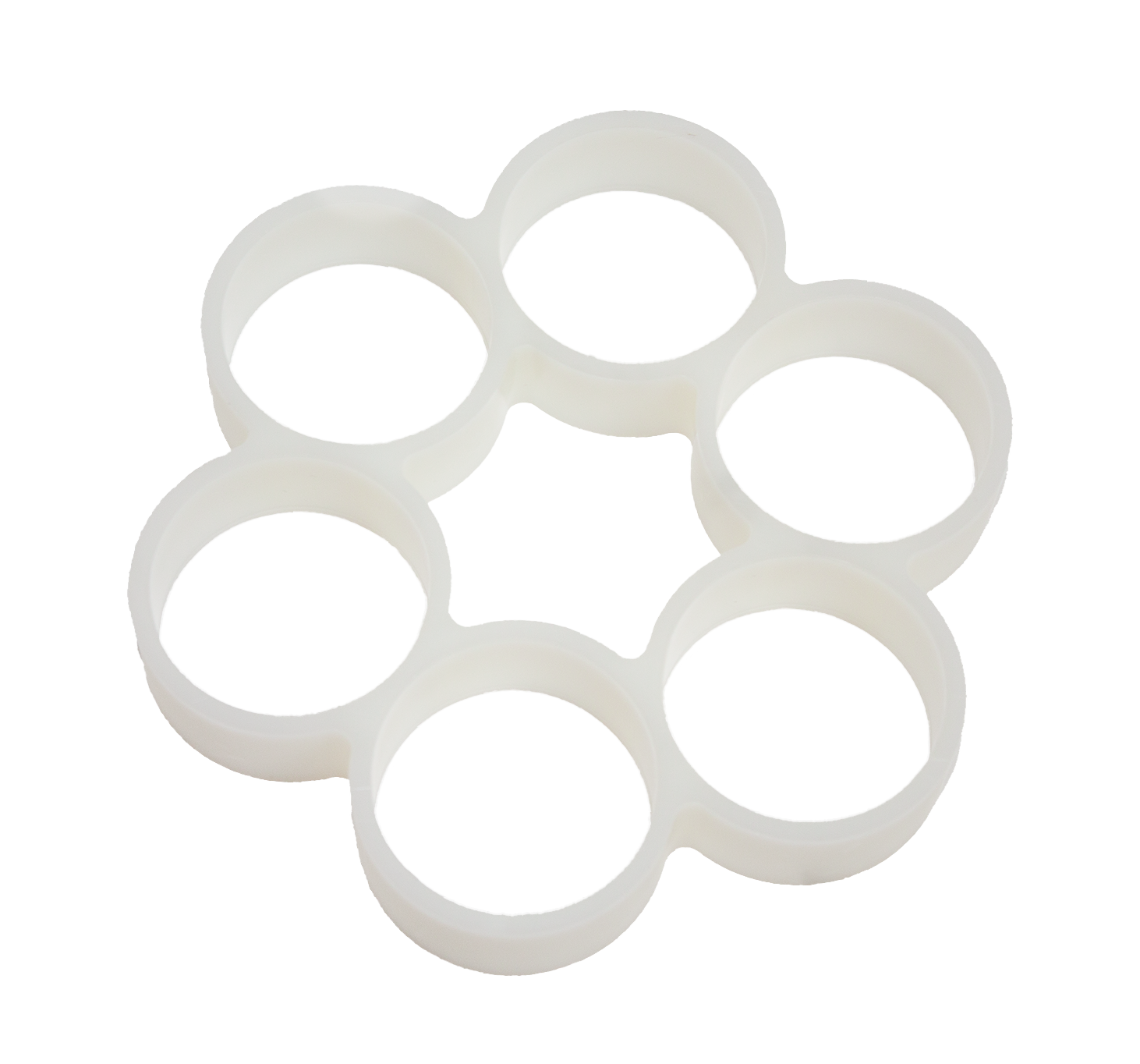

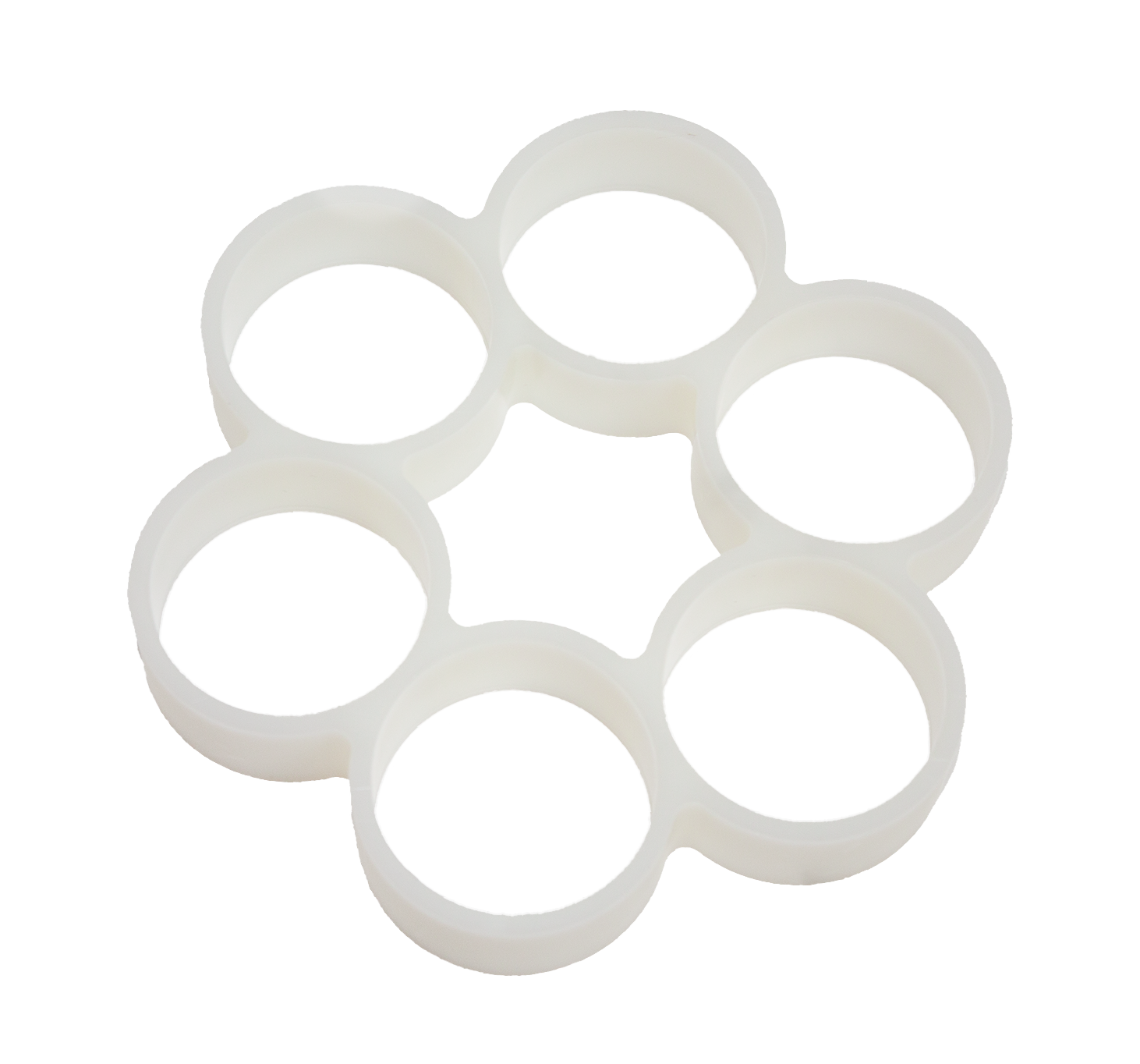

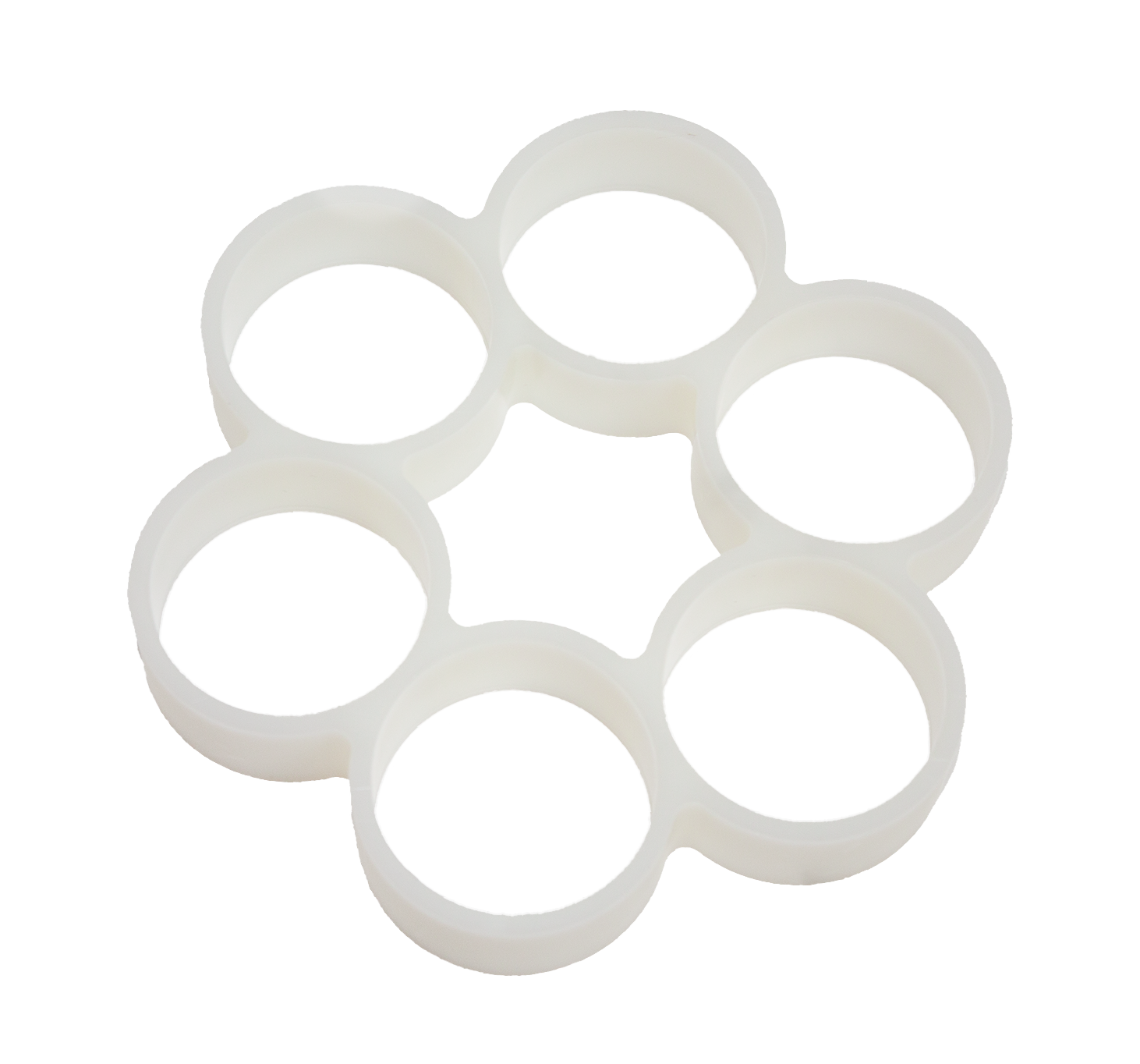

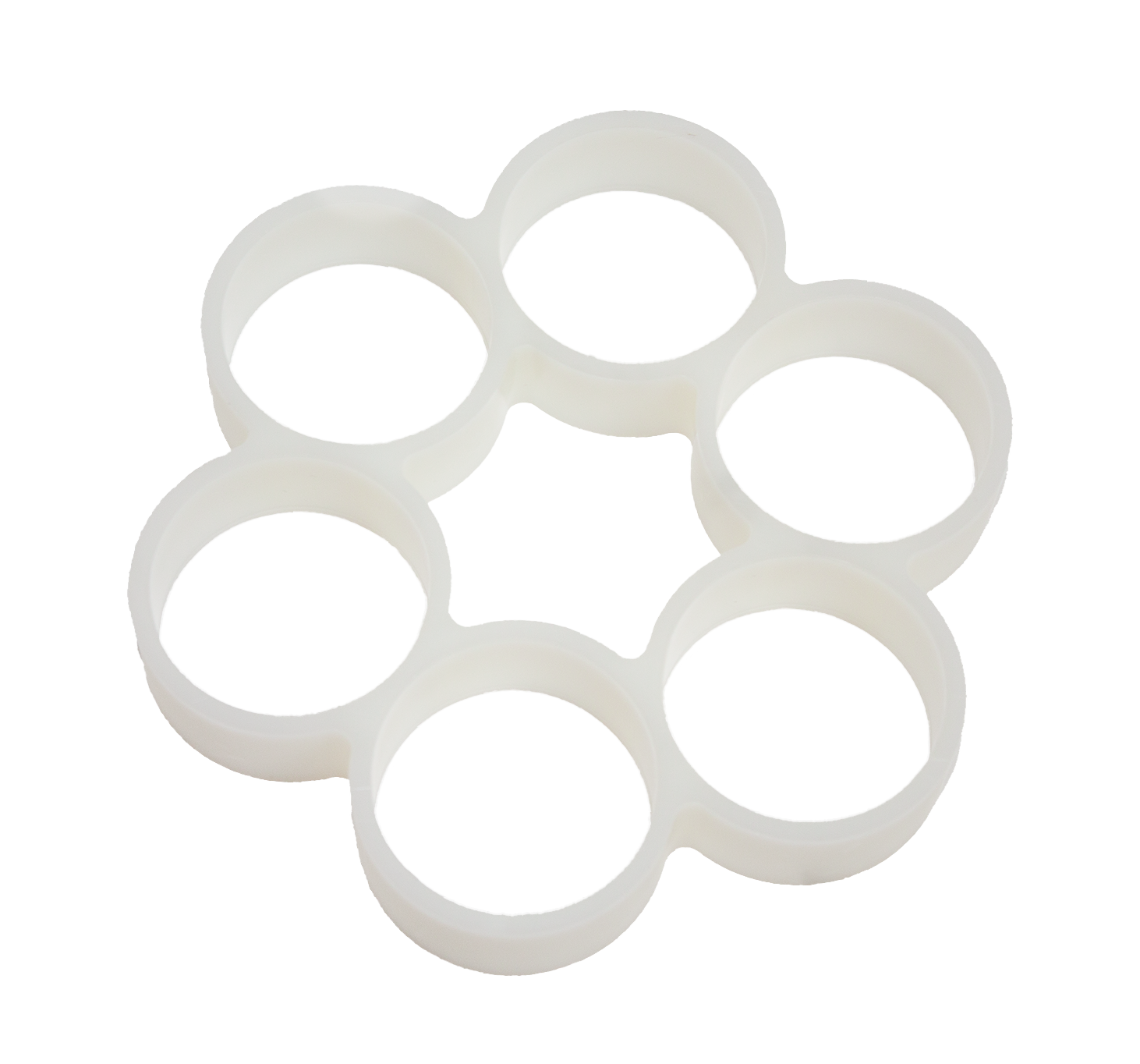

6 FDA-approved nylon sliders create a honeycomb structure that maximizes mesh contact, delivering superior particle dislodging on vibratory screeners

Or Sign in with your Shop account.

Have questions? Call us at (866) 265-1575 or email support@screenerking.com.

Get what you need, when you need it. Expedited shipping available for most items. Contact us for more details!

Error

discount code automatically applied at checkout.

Your cart has been updated